Did You Know That a Mobile Home Does Not Have 2 X 4s in Its Roof

Understanding how manufactured homes are constructed tin can aid y'all remodel or modify a home. This is especially truthful when yous take to supercede the flooring or movement walls in a mobile home. Knowing the construction methods that are involved, and the order of construction, tin can help you plan your project ameliorate and save money.

Manufactured Home Construction Basics

Steel Chassis

Both single wides and double wides (which are basically but two single wides) sit on a steel chassis.

Steel beams with slight curvatures are welded together to create a cambered chassis.

This is done to assistance even out or distribute the weight of the abode. These curves are barely noticeable but are vital to a strong manufactured home that can withstand vibrational forces and transportation at 55 mph.

The camber or curve of the steel chassis helps the home blot shocks and distribute weight more than efficiently.

The all-time chassis are built with American steel. Cheaper Chinese steel is used in a few builders – endeavour to stay away from those if you lot have a selection.

Outriggers

The 'side to side' beams have outriggers on the ends. Outriggers are the tapered edges that may or may not go to the very edge of the home.

Cheaper manufactured homes will not accept outriggers that get to the very edge of the home.

Outriggers that go to the very border are better because they hold the weight of the walls and the roof improve. If the outriggers aren't stiff plenty or doesn't extend out far enough, the home'south perimeter walls and roof can sag.

Besides the chassis and roof-down structural integrity, manufactured homes are built much like site-built homes.

Floor Joists

Once the chassis has been built to specifications, the builders will utilise a jig or template to built the floor joists from 2x6s or sometimes 2x8s for the higher quality homes.

Palm Harbor homes uses computer aided design programs to aid design their floor joists for each model.

The heating and cooling vents, plumbing lines, and electrical cables will exist installed through the floor joists. In some models, the ductwork and electrical volition be ran through the roof trusses.

Next, the subflooring and flooring covering will exist laid.

How Walls are Built in Manufactured Homes

Walls are built using wood boards chosen studs. Studs are the vertical boards and are ordinarily 2″ x four″ and spaced every 16″ in a manufactured home. That's what the term sixteen″ OC, or 'on center' ways in structure lingo. Better quality manufactured homes will have 2×half dozen studs and more than affordable homes volition take 2x3s. State laws and air current zones will determine how your manufactured home is synthetic.

Interior walls, sometimes called partition walls considering they separate space and have no load bearing qualities, can be 2x2s and spaced 24″ autonomously.

The vertical studs are held together with horizontal boards called bottom plates and acme plates. Domicile Tips shares a helpful illustration of the parts of a wall:

Walls around doors and windows are built differently to distribute weight downward the sides of the rough opening. Structural headers are used above the doors and windows to reinforce the expanse. Oftentimes trimmer or king studs volition exist used (sometimes both simply not as often).

How Walls are Fastened to Joists and Trusses

The bottom plate of an interior wall is nailed into the floor joists. The floor and the roof will sandwich the walls to create a structurally sound wall.

The perimeter walls of a manufactured dwelling are attached to the flooring joists using nails and 26 gauge metal straps every bit shown below. These are besides called hurricane straps.

The perimeter walls are fastened to the roof trusses using metallic straps and nails, as shown beneath.

If your manufactured dwelling house'south roof truss sits completely upon a top plate it usually indicates a load bearing wall.

Double Wides

In reality, double wides are just two unmarried wides. Each piece of a double wide has its ain integrity and strength but together information technology creates an even stronger home.

In the epitome below, you see one half of a double wide that has the interior and perimeter walls installed. Notice in that location is no roof, nevertheless. Roofs are built separately from the rest of the home and installed subsequently all interior work has been done.

Double Wide Roofs

Double wides employ roof trusses that are

Once the roof is installed over the walls it will create a potent web of structural integrity.

Exterior Construction on New Manufactured Homes

Some manufactured home builders do things a little differently. Some brands will put the roof on beginning and and so add the exterior sheathing, others will add together the sheathing on before the roof.

Jacobsen Homes does the latter. Jacobsen Homes released a video on Youtube that shows their manufactured home structure process. Of all the videos I've watched they seem to call out other brands more frequently for cutting corners or using cheaper materials – I enjoy that.

Exterior sheathing should be OSB or plywood. There is a product petrochemical product called Thermo-Ply. It's cheaper and doesn't seem to withstand the elements as well.

Video Tours and Structure Videos

Nosotros have added several of the summit manufactured abode builder'southward construction videos beneath. This should brand it like shooting fish in a barrel for you to see how each company differs. Recollect, though, a few of the brands below are owned by the same corporation so there actually isn't much of a deviation.

Also, keep in mind that these brands are showing their best models in these videos and therefore their best construction. Most models that builders offer volition non have the materials mentioned.

How Manufactured Homes are Constructed at Clayton Homes

How Manufactured Homes are Constructed at Jacobsen Homes

How Manufactured Homes are Synthetic at Palm Harbor

How Manufactured Homes are Constructed at Champion Homes

How It's Made Tv Prove Covers Manufactory-Built Homes

How Manufactured Homes are Constructed at Schult Homes

How Manufactured Homes are Constructed at Golden Due west Homes

10 Smart Upgrades to Get When Buying a New Manufactured Dwelling house

A Meliorate Expect Inside a Manufactured Dwelling

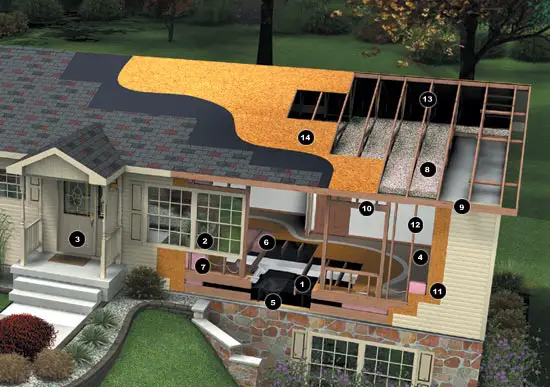

If you want to visualize a double wide's edifice process, this image should assistance you. I found it at Frey's Mobile and Manufactured Home Sales website.

1. ii×10 #2 SPF or better floor joists on 16″ centers.

2. Perimeter heat with wall mounted registers and boots.

3. Shaw Acclamation sixteen ounce casual texture carpet with 5 pound rebond pad.

4. 2×6 Stud SPF or better placed on 16″ centers.

v. ii×10 headers in a higher place all windows and doors.

half-dozen. vii/16″ OSB exterior capsule.

7. R-19 Owens Corning Fiberglass wall batt insulation.

8. R-33 Cellulose Roof Insulation.

9. Optional 7/12 roof pitch with 50 or 70-pound snow load.

10. 2×half-dozen Fascia plate.

11. vii/16″ OSB exterior roof sheathing.

12. Architectural Roof Shingles.

13. Total-finish drywall throughout the home.

14. Dual pane vinyl, unmarried hung – unmarried tilt windows.

15. 36×80 vinyl clad steel insulated six-console door with storm front and rear.

Larn about the iii levels of quality and cost here.

Conclusion – How Manufactured Homes are Synthetic

Knowing how manufactured homes are constructed is smart for those looking to remodel an older mobile home or buy a new manufactured home.

Over the years, the manufactured abode builders accept tweaked their edifice processes down to a fine science and the quality of the homes has increased significantly.

Building a home in a factory is a safer and far more than affordable method of dwelling house structure.

Advanced calculator-aided pattern, specialized machinery, and tight inventory control has immune brands to build manufactured homes at half the cost per square foot every bit a site-built home.

Amalgam a home inside a temperature controlled manufacturing plant with well-trained employees that know they volition take a chore tomorrow creates a college quality product. People that work regular shifts is the best accommodating method for home construction.

As always, thanks then much for reading Mobile Abode Living!

Updated April 13, 2019 (MMHL does non endorse or recommend one manufacturer over some other. Each manufacturer has their ain strengths and weaknesses.)

normanoushavinge95.blogspot.com

Source: https://mobilehomeliving.org/how-manufactured-homes-are-constructed/

0 Response to "Did You Know That a Mobile Home Does Not Have 2 X 4s in Its Roof"

Post a Comment